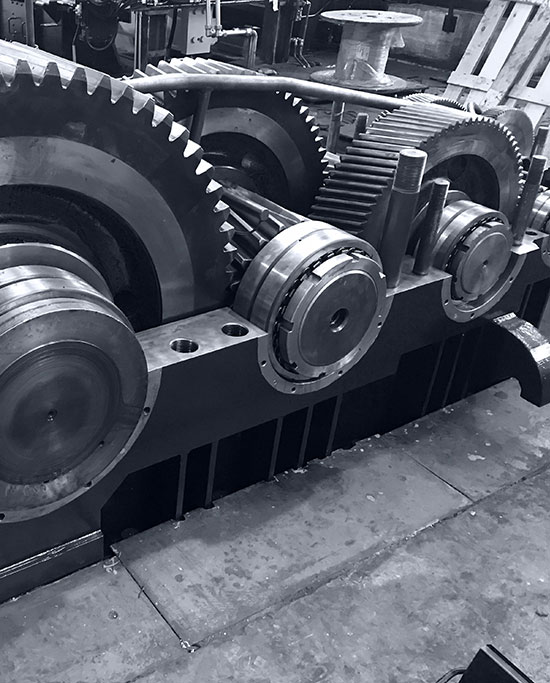

It is impractical to build an oil tight casing around the gear set to allow use of a fluid lubricant. This situation occurs most often with large slow-moving gears or gears which operate for a short period of time. What is needed is a lubricant that can be brushed or sprayed from time to time and which will resist being thrown off or wiped off the teeth.

Our open gear greases are formulated to meet the unique challenges of lubricating a wide range of exposed gears, including open gears on sugar mill crushers, ring gears on rotary kilns, gearing on draglines and in quarries, foundries and many other operations.

Key Features:

Excellent water resistance, Shear stability in metal contact

Open Gears

Products: SOG 600

Thickening Agent: Aluminum Complex

NLGI: 0

Features: Specially designed for high loading applications which are widely used in power mining, petrochemical and cement industries.

Products: SOG 800

Thickening Agent: Alassca Complex

NLGI: 0

Features: Widely used in slow-moving open gear especially in wet environment. Offers excellent water resistance and protection from wear.

Products: SOG 800/2

Thickening Agent: Alassca Complex

NLGI: 2

Features: Widely used in slow-moving open gear especially in wet environment. Offers excellent water resistance and protection from wear.

Products: SOG 3000, SOG 3000A, SOG 3000B

Thickening Agent: Aluminum Complex

NLGI: 0, 00, 000

Features: Tacbecon SOG 3000 series, specially designed for extreme loaded applications, are formulated with superfine graphite which enhanced wear resistance and shear stability in metal contact.